Forge and Bond wheels

Forge and Bond are making carbon wheels using nylon rather than resin in their carbon fibre mix.

Carbon fibre is an amazing product, of that there’s no doubt. A “cloth” that when impregnated with resin, put into a mould and heated under pressure, becomes a super-tough material. It can be moulded into complex shapes and tuned to be flexible or rigid. But it comes with a lot of environmental negatives. The resins used are highly toxic and the finished product needs a lot of finishing that also produces toxic waste. This waste can not be re-used and the finished product can’t be economically recycled. Also the pre-impregnated cloth has a limited life-span and has to be kept refrigerated during storage, adding to the environmental cost.

Is there an alternative?

US company Forge and Bond have come up with a different approach to carbon fibre products. They are using nylon rather than resin as the “glue” that holds the carbon fibre together: they call this material FusionFiber. The long-chain nylon polymers used in FusionFibre have a number of advantages over resin.

First off they are able to flex, unlike resin. This allows the rim rim to absorb impacts as the fibres flex at a microscopic level. According to Forge and Bond the rims provide 50% more damping compared to resin impregnated ones. And their rims have been tested to withstand a minimum of 275% of the UCI’s impact resistance test.

Thermoset versus thermoplastic

Also the two types of carbon fibre differ in the way they act after they have been heated and moulded. Resin impregnated carbon fibre is a thermoset material, once it has cured the shape is final. Using nylon means you have a thermoplastic material, heat it and it returns to its original form. This means you can use it again to make other parts, like handlebars, stems or tyre levers! Yes Forge and Bond sell what they claim are the toughest tyre levers out there: made from scrap FusionFibre!

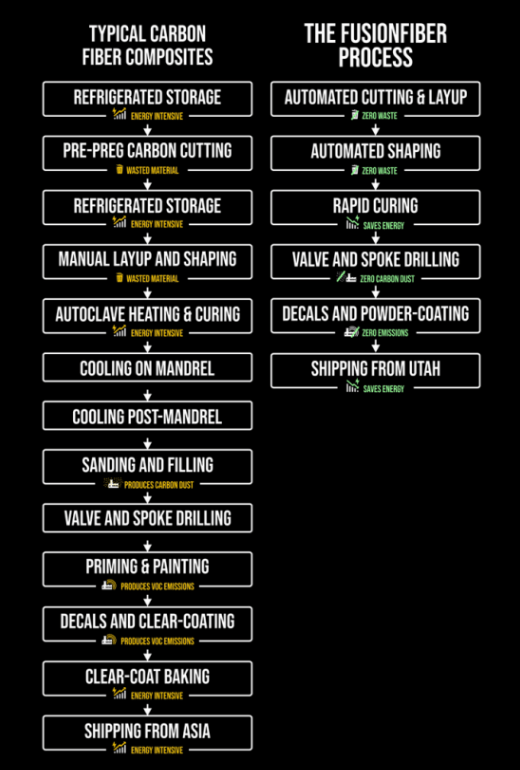

So they’re tough and they’re light, what other advantages are there? Well the whole process of cutting, laying up and shaping the wheels is automated, cutting down on waste. The curing process is a lot shorter as well, cutting down on energy usage. And once the rim is ready it doesn’t need sanding or de-burring, processes which create toxic dust that needs to be dealt with. Any waste, like off-cuts can be shredded and used to create other products. Once the wheels have been used and abused they can be sent back and recycled to be used again in new products.

Forge and Bond FusionFibre process

So far Forge and Bond have two Mtb and a gravel wheelset. The F+B 30 EM is their enduro racing/trail-riding wheelset. It comes in 28 or 32 spokes and uses Industry Nine Hydra Classic boost hubs and weigh 1982g. The F+B 25 XC NICA wheels are XC/marathon race wheels. They have 28 spokes and use Industry Nine 1/1 hubs and weigh in at 1560g. Moving on to gravel and you have the F+B 25 GR wheels. These have Industry Nine Torch CL hubs, 24 spokes and weigh in at 1510g. There’s an All Mountain wheelset on the way and they’re also working on road wheels. And with FusionFibre’s damping they could be a god-send on our terrible roads!

What’s the future?

So could thermoplastic carbon fibre be the way forward for the bike industry? Resin based carbon fibre is dominant because it was the predominant material that was used in the aerospace industry. And with the bike industry copying those techniques resin just became the norm. But with aerospace manufacturers now looking to use more thermoplastic, things could be about to change.

It’s not just Forge and Bond that are developing alternatives, companies like REIN4CED and Guerrilla Gravity are also developing alternatives. So in the coming years we’ll still be riding carbon fibre however it will come with less of an environmental cost: which can only be a good thing.

We’ll try and get a set of Forge and Bond’s wheels on test and let you know how they perform. Keep an eye out for any news on this. In the meantime check out Forge and Bond’s website.

You must be logged in to post a comment.